COOPERATIONS

University College London

/Prof. Ian W. Boyd/

1. Photodegradation of polycarbonate under narrow band

irradiation at 172 nm

Abstract

Photostability of polymers is an important issue since most polymers tend to loose their original properties upon exposure to light, especially to ultraviolet radiation. Polycarbonates are widely used industrial materials because of their excellent properties, which includes transparency, high tensile strength, impact resistance and rigidity. In this paper we present results on 172 nm photodegradation of polycarbonate (PC) films. PC films of 50 µm thickness were irradiated for up to 20 minutes using a Xe2* excimer lamp system. Ex-situ UV visible spectroscopic investigation of the treated films revealed the appearance of two strong absorption bands at 279 and 317 nm and a third broad band centred around 380 nm whose intensity increased linearly with illumination time. The morphological changes were characterised by Atomic Force Microscopy and resulted in a gradually increasing roughness, being a linear function of irradiation time. The interpretation of the observed chemical degradation is based on Attenuated Total Reflection IR and X-ray photoelectron spectroscopic measurements which show cleavage of the aromatic C-C and carboxylic CO-O bonds together with some nitrogen incorporation into the surface layer of the irradiated films.

2. Comparative tensile strength study of the adhesion

improvement of PTFE by UV photon assisted surface processing

Abstract

Polytetrafluoroethylene (PTFE) is notable for its non-adhesive and non-reactive properties. A number of technologies can potentially benefit from the application of PTFE, but these characteristics restrict the ability to structuring its surface. In this paper we present results on two ultraviolet photon assisted treatments of PTFE. The originally poor adhesion was significantly improved by both 172 nm excimer lamp and 193 nm excimer laser assisted surface treatments. While Xe2* lamp irradiation, applied in a modest vacuum environment, was sufficient by itself to improve adhesion, the ArF laser process was only effective when the irradiated interface was in contact with 1,2-diaminoethane photoreagent. It was found that the tensile strength of an epoxy resin glued interface created on treated surfaces depended strongly on the applied number of laser pulses and lamp irradiation time. Laser treatment caused fast tensile strength increase during the first 50-500 pulses, whileafter this it saturates slowly at about 5.5 MPa in the 500-2500 pulse domain. The excimer lamp irradiation resulted in a maximum tensile strength of approx. 10 MPa after 2 minutes irradiation time which reduced to about 65% of the peak value at longer times.

- B. Hopp, Zs. Geretovszky, I. Bertóti and I. W. Boyd: Comparative tensile strength study of the adhesion improvement of PTFE by UV photon assisted surface processing, Appl. Surf. Sci. 7387, 2001

- Zs. Geretovszky, B. Hopp, I. Bertóti and I.W. Boyd: “Photodegradation of polycarbonate under narrow band irradiation at 172 nm”, Appl. Surf. Sci. 7387, 2001

Foundation for Research and Technology Hellas

/Prof. Costas Fotakis/

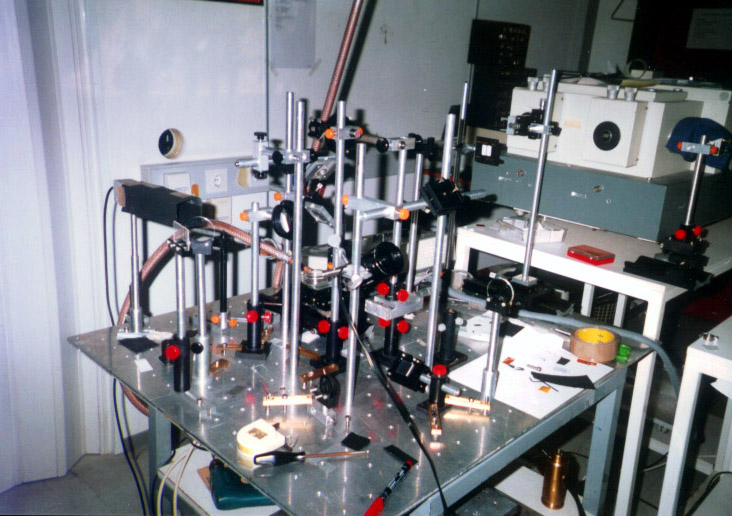

1. Time-resolved investigation of the

transient surface reflection changes of subpicosecond excimer laser ablated

liquids

Abtract

A single shot measurement of subpicosecond time resolution was developed to investigate the transient surface reflection changes of excimer laser ablated liquids during one UV pulse. Polysilicone oil, methylmetacrylate, styrene and water were irradiated by a 500 fs KrF excimer laser. The irradiated area was illuminated by an optically delayed 496 nm 500 fs probe dye laser pulse at angle of 45o incidence. As the tilted probe beam scanned along the ablating surface, the temporal increase of the reflected intensity appeared as spatial modulation of the probe beam. The maximum reflectivities were 1.5-2.5 times higher than those of the initial samples. The reflectivity increase is caused by a plasma mirror induced by the subpicosecond excimer laser ablation. In the case of styrene it was found that higher fluence resulted in higher increase of reflectivity.

When increasing the UV absorption of methyl(metacrylate) by naphthalene doping the reflectivity enhancement both via its effect on the absorption coefficient as well as through its own photoionization by 2-photon absorption was observed.

- B. Hopp, Zs. Tóth, K. Gál, Á. Mechler, Zs. Bor, S. D. Moustaizis, S. Georgiou and C. Fotakis: “Time-resolved investigation of transient surface reflection changes of subpicosecond excimer laser ablated liquids” Appl. Phys. A 69, S191-194, 1999

- Zs. Tóth, B. Hopp, Á. Mechler, Zs. Bor, S. D. Moustaizis, S. Georgiou, C. Kalpouzos and C. Fotakis: “Reflectivity transients on solid surfaces induced by 0.5 ps high power excimer laser irradiation”, Laser Physics vol.10, 241-245, 2000

2. Expansion velocities of 0.5 ps KrF excimer laser induced plasma by Doppler-shift

analysis of pump and probe measurements

Abtract

High gradient laser plasma is formed

by focused KrF laser pulses (248.3 nm, 450 fs,

1013 W/cm2) on liquids (water, styrene) and solids

(silicon, aluminum, and polyimide). The hydrodynamic expansion of the plasma

was studied by measuring the blue Doppler-shift of reflected probe pulses which

was produced by a delayed dye laser (496.6 nm,

450 fs). The Doppler-shift corresponds to the velocity of the reflecting

surface of the plasma which is defined by the critical electron density.

Expansion is investigated as a function of delay time and laser intensity. The

reflecting surface of the plasma accelerates over 1–2 ps after the onset of the

ablating laser pulse.With increasing intensity up to

2×1013 W/cm2 the maximum average velocities are

monotonously increasing up to ∼ 1–2×105 m/s.

- Z. Tóth, B. Hopp, J.

Klebniczki, N. Kresz, Zs. Bor, D. Anglos, C. Kalpouzos, C. Fotakis:

„Expansion velocities of 0.5 ps KrF excimer laser induced plasma by

Doppler-shift analysis of pump and probe measurements”, Appl. Phys. A 79,

1287-1290 2004

University of Ulm

/Prof. Othmar Marti/

1.

Adhesive and morphological characteristics of surface chemically modified

polytetrafluoroethylene films

Abtract

In the present paper, we

report an experimental determination of adhesive and topographic

characteristics of chemically modified surface of polytetrafluoroethylene

(PTFE) films. The surface chemistry was modified by ArF excimer laser

irradiation in presence of triethylene-tetramine photoreagent. The applied

laser fluence was varied in the range of 0.4–9 mJ/cm2,

and the number of laser pulses incident on the same area was 1500. To detect

the changes in the adhesive features of the treated Teflon samples, we measured

receding contact angle for distilled water and adhesion strength, respectively.

It was found that the receding contact angle decreased from 968 to 30–378 and

the adhesion strength of two-component epoxy glue to the treated sample surface

increased from 0.03 to 9 MPa in the applied laser

fluence range. Additionally, it was demonstrated that the adhesion of human

cells to the modified Teflon samples is far better than to the untreated ones.

The contact mode and pulsed force mode atomic force microscopic investigations

of the treated samples demonstrated that the measured effective contact area of

the irradiated films does not differ significantly from that of the original

films, but the derived adhesion force is stronger on the modified samples than

on the untreated ones. Hence, the increased adhesion of the treated Teflon

films is caused by the higher surface energy.

- B. Hopp, N. Kresz, J.

Kokavecz, T. Smausz, H. Schieferdecker, A.

Döring, O. Marti, Z. Bor: „Adhesive

and morphological characteristics of surface chemically modified

polytetrafluoroethylene films”, Appl. Surf. Sci. 221 (1-4): 437-443

JAN 15 2004

2.

Investigation of pulsed laser deposited crystalline PTFE thin layer with pulsed

force mode AFM

Abtract

Teflon thin films were

prepared via pulsed laser deposition using an ArF excimer laser (193 nm,

FWHMs20 ns) from pressed powder pellets. The applied fluence was 6.25 J/cm2 , the number of pulses was 10 000, the pressure in

the vacuumchamber was 2=10 Torr and the substrate temperature was 250

- N. Kresz , J. Kokavecz , T. Smausz , B. Hopp , M. Csete , S. Hild and O. Marti: „Investigation of pulsed laser deposited crystalline PTFE thin layer with pulsed force mode AFM”, Thin Solid Films, Volumes 453-454, Pages 239-244 April 2004

3. Investigation of incubation in ArF

excimer laser irradiated poly(methyl-methacrylate)

using pulsed force mode atomic force microscopy

Abtract

An atomic force microscopic

method to study the incubation states of UV laser irradiated polymer samples is

presented. Targets were illuminated by different number of pulses at 5.8 and 8.9 mJ/cm2 fluences. The induced adhesive and

morphological changes were investigated simultaneously by an atomic force

microscope equipped with a pulsed force mode extension. Importantly, below 100

pulses morphological changes were not observable while significant changes in

the adhesion were found as a result of the incubation at 8.9

mJ/cm2 fluence. This method allows the imaging and detection of the whole laser

modified area with nanometer resolution.

- B. Hopp, T. Smausz, J.

Kokavecz, N.

Kresz, Z. Bor, S. Hild, O. Marti: „Investigation of incubation in ArF

excimer laser irradiated poly(methyl-methacrylate)

using pulsed force mode atomic force microscopy” J. Appl. Phys. 96,

5548-5551 2004